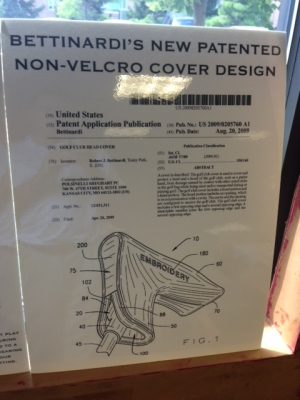

By Jeffrey A. Rendall, Images courtesy of Bettinardi Golf

TINLEY PARK, IL – Being a golf equipment junky has its benefits and its drawbacks. The benefits include knowing great value and the drawbacks are only discovered when perusing your credit card bill every month.

All told, the benefits usually prevail – you know good stuff when you see it. That’s how I knew right away that Bettinardi Golf was for real. Everything they make looks like a finely crafted piece of art.

After delving a little deeper into the matter, my instincts were confirmed. The Tinley Park, Illinois company is a true family-owned and operated business, and everything they produce is made here in the U.S.A.

|

How’s that for a little native pride?

Sam Bettinardi is the son of company founder and putter-making legend Bob Bettinardi. Sam serves as the company’s Vice President of Sales and Marketing and he’s certainly proud of the Bettinardi name and his dad’s success.

“Bettinardi Golf began in 1991 when Bob Bettinardi saw a putter in a golf shop that said it was milled on a Bridgeport milling machine. My father comes from a rich background of milling and machinery and thought to himself that surely he could mill putters with his C.N.C. machines,” Sam explained.

It’s a good thing Bob knows what a C.N.C. machine is, because I didn’t have a clue.

|

According to Wikipedia, C.N.C. stands for computerized numerical control. “Numerical control is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone.”

Don’t feel bad if you don’t get it. The machines make great golf equipment, that’s all I need to know.

Sam continues with the story, “A few short months later he was milling putters and sending them to various companies. It was unanimous in the putter industry that Bob Bettinardi knew his way around a C.N.C. milling machine. By 1999 Bob took his putters out on tour and before you knew it, Jesper Parnevik picked one up and won the tournament that weekend by shooting -23 with only 99 putts!”

Yes, those Tour guys are good – but they don’t win on talent alone. Innovators like Bob Bettinardi help them succeed.

|

Bob still oversees the entire Bettinardi operation and Sam says they can walk twenty feet from their offices onto the shop floor to inspect all aspects of the putter process.

In addition to the obvious quality of manufacture of Bettinardi products, you’ll likely notice the unique honeycomb pattern on many of the putter faces. Milled faces and inserts are nearly universal these days, yet the honeycomb appears quite a bit different.

Again, Sam explains. “Back when my dad started milling putters, almost all the faces were styled like our Super-Fly Mill face. In 1998, he decided to take closer look at the putters he was milling by using a very complex machine tool which put the face milling under a microscope.”

“He learned that the combination of the horizontal movement of the milling tools and the heat that it produced while milling created a concave fixture in the face.”

|

Let’s see… concave means having an outline or surface that curves inward like the interior of a circle or sphere.

Convex means curving outward… think of the domed greens at Pinehurst.

Needless to say, a putter face that curves inward can be problematic. “All these years, every top end putter company was producing these concave faced putters and the putters were not even flat. My father and his team of engineers decided to mill the putters vertically just to see what would happen and find out if he could create a flat surface on the putter face.”

“The result is the Honeycomb face milling.”

|

For our test we chose the new Bettinardi Studio Stock 16 putter. The company website describes it: “Milled from soft carbon steel, the Studio Stock 16 has an impressive semi-circle shape that features a double bend shaft, flowing right into this face balanced mallet. A custom radius tool helped shape the back flange that delivers crucial weight displacement for ideal perimeter weighting.”

“The one-piece milling harmonizes effortlessly with the new Super Fly-Mill face, promoting an enjoyable, yet crisp feel when struck. The new Olympic Bronze PVD finish offers this mallet its unique beauty!”

The bronze is what I noticed first. It’s a finish you used to see a lot, though it isn’t all that common today – at least in putters.

Sam says the basic idea behind the Studio Stock line “is to give our customers two different looks with a mallet and blade, both in different finishes.”

|

“The Olympic Bronze finish gives the Studio Stock line a unique look that is unmatched. Along with the distinguished finish, the Studio Stock series are the only putters in our line that has a super Fly-Mill face which promotes a softer, crisper feel at impact.”

“We are on the cutting edge of face-milling technology and unique PVD finishes, where we try to push the envelope year after year.”

Again, PVD means “physical vapor deposition,” a process used to create a very durable, corrosion and tarnish resistant finish. This is similar in appearance to highly polished brass.

Thank God for online encyclopedias. I know I've learned a lot today.

|

All the fancy terminology aside, the Bettinardi Studio Stock 16 is excellent at getting the ball in the hole. It has a very soft feel, is easy to align and is pleasant to the eye. Add in the always terrific Bettinardi head covers and you’ve got quite a product.

Bettinardi putters are pricey – don’t expect to find one in the bargain bin at the local driving range. But again, you get what you pay for.

Again, they’re beautiful in addition to functioning well. When asked if putter-making is more art or science, Sam says it’s a combination of both. “We believe that the putter must look great to the golfer’s eye which is ‘art.’ The more confidence you can have in your putter the better you will putt.”

“But there still needs to be science in putting which involves designing putters that fit the golfer’s putting stroke, i.e, more face-balanced options, MOI designs, and better face milling technology.”

MOI means… just kidding.

As for trends in putter design, “We believe that the arm-lock method of putting is leading the industry as far as new putting technology is concerned. The way Matt Kuchar putts has really given a lot of players who have used the belly and long putter an opportunity to make an easy transition into an alternative putting style.”

If there’s a better way to make putters, Bettinardi Golf will find it. You owe it to yourself to take a look at them if you’re in the market for a high-end putter.

Then you too will know quality when you see it.

Details:

Bettinardi Golf

7800 Graphics Drive

Tinley Park, IL 60477

Phone: (708) 802-7400

Fax: (708) 802-7401

Website: http://www.bettinardi.com/

Dealers: http://www.bettinardi.com/dealer

Check the website for more locations and availability.

Bettinardi also features quite a selection of wedges and accessories.

| Related Links | Comments on this article? | |

|

Maryland National Golf Club Hollow Creek Golf Club Rocky Gap Resort PB Dye Golf Club in Ijamsville Whiskey Creek Golf Club |

E-mail Jeff Rendall, Editor: jrendall@golftheunitedstates.com |